Product Features

Product Features| Name | Electrical insulating laminated wood | |||||

| Test item | Unit | Test method | ||||

| Apparent Density | g/m3 | IEC 61061-2:2001 | ||||

| Moisture content | % | |||||

| oil adsorption | % | |||||

| Thickness variation before and after oil absorption | % | |||||

| Compressive strength | normal | Vertical to the layers | Mpa | Refer to ISO604: 1993 | ||

| parallel to the layers | ||||||

| 90℃ | Vertical to the layers | |||||

| parallel to the layers | ||||||

| Flexural strength | normalcy | MD | Mpa | IEC 61061-2:2001 | ||

| CD | ||||||

| 90℃ | MD | Mpa | ||||

| CD | ||||||

| Flexural modulus | normalcy | MD | Mpa | |||

| CD | ||||||

| 90℃ | MD | |||||

| CD | ||||||

| Compressibility perpendicular to the laminations | C | % | ||||

| C rev | ||||||

| Impact strength parallel to the laminations | Vertical to the layers | kj/m2 | ||||

| parallel to the layers | ||||||

| Contamination of liquid dielectric |

| |||||

| Electric strength perpendicular to the laminations | MV/m | |||||

| Breakdown voltage parallel to the laminations | KV | |||||

| Shrinkage after drying | A direction | % | ||||

| B direction | ||||||

| thickness | ||||||

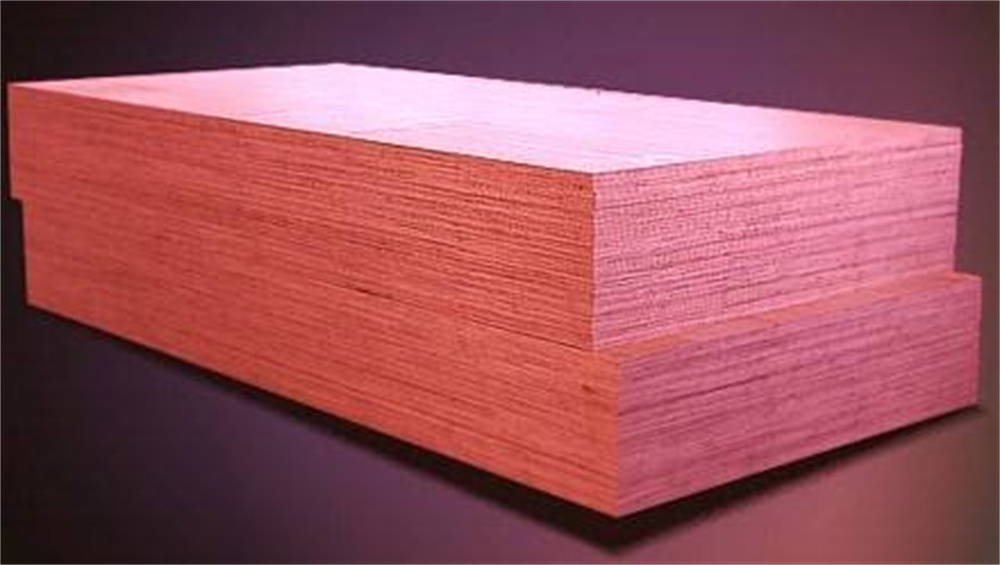

Product DescriptionIt replaces steel plates, insulating cardboard, epoxy cardboard, etc. The application of epoxy glass cloth board in these aspects reduces the self-weight and material cost of the transformer. Electrical laminated board is a veneer made of high-quality birch wood, which is cooked, peeled and dried. After being coated with special insulating glue, it is made by high temperature and high pressure.

Product DescriptionIt replaces steel plates, insulating cardboard, epoxy cardboard, etc. The application of epoxy glass cloth board in these aspects reduces the self-weight and material cost of the transformer. Electrical laminated board is a veneer made of high-quality birch wood, which is cooked, peeled and dried. After being coated with special insulating glue, it is made by high temperature and high pressure. Product SpecificationMaximum size of plate (length × width × thickness): 4000×3000×120(mm) Common specifications and dimensions of plates (length × width × thickness): 3000×1500×(10—120) (mm), 2400×2000×(10—120) (mm)

Product SpecificationMaximum size of plate (length × width × thickness): 4000×3000×120(mm) Common specifications and dimensions of plates (length × width × thickness): 3000×1500×(10—120) (mm), 2400×2000×(10—120) (mm)